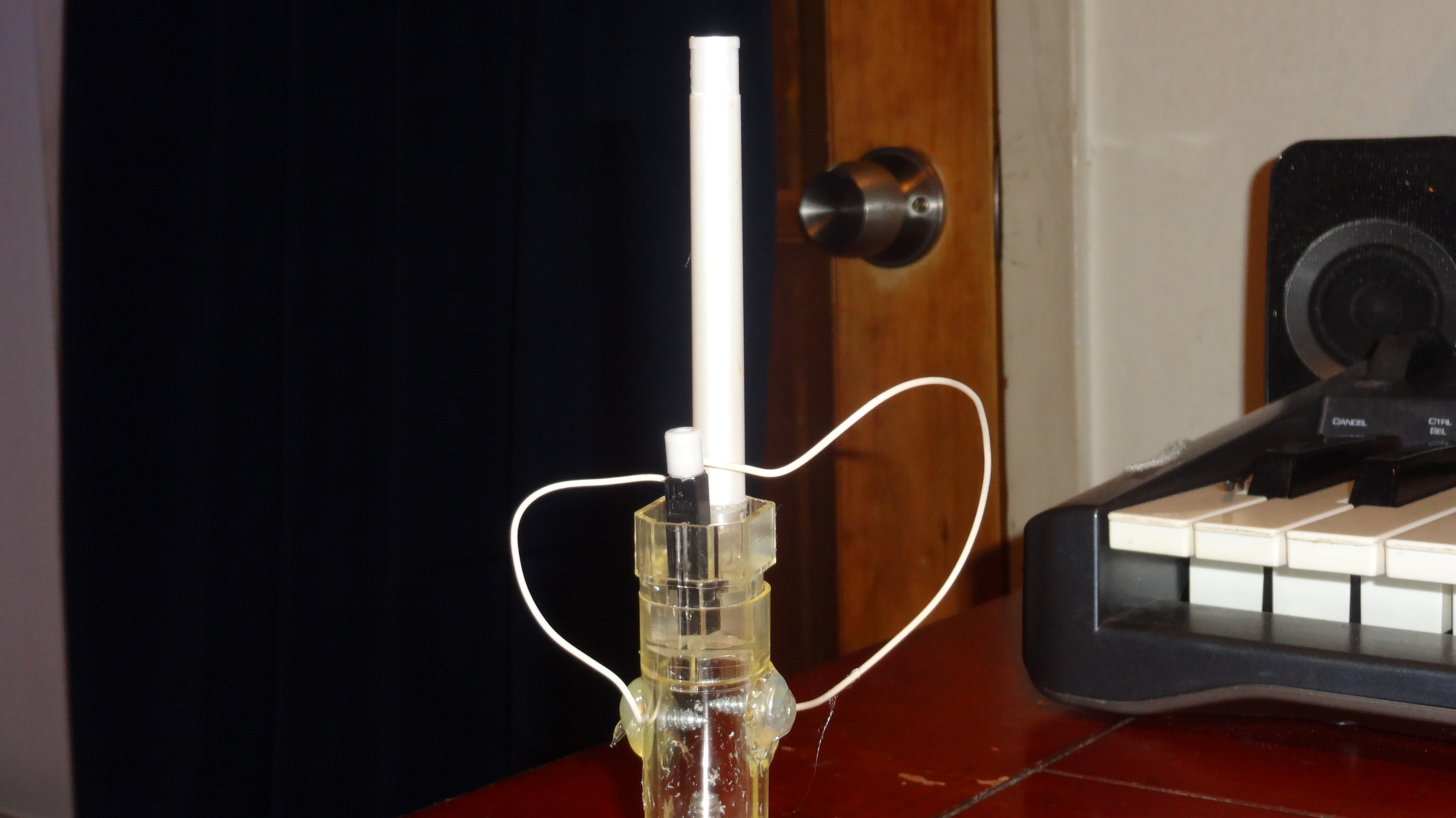

Continuing to work on the PiTurretCam project. Previously I demonstrated the basic hardware configuration, wiring, and was able to demonstrate functionality by manually executing commands in the console. Ultimately, I envisioned a light weight service which handles the ugly details of moving the servo and running commands against the camera. A service that allows for the end user to send a simple set of commands to interact with the device, or even a graphical user interface. This past week I had some time to start mapping out and coding up the service(s). The language of choice here was Ruby (familiarity). A set of custom modules and classes were drafted and coded to support the various actions and attributes associated with operating a camera and servo. The popular community gem event machine loads the classes and responds to a TCP port to a simplified set of commands that open a wide array of hardware control an end user. A secondary service (sinatra application) provides a simple RESTful API as well as an index page equipped with logic to interact with said API. The basic functionality currently provided are, turret motion, camera control, soon to come features are storage management, more granular control of the camera and it's features, wi-fi (separate from the software side but much needed, I mean, what is a camera that doesn't move?), self configuration and image/video post processing.

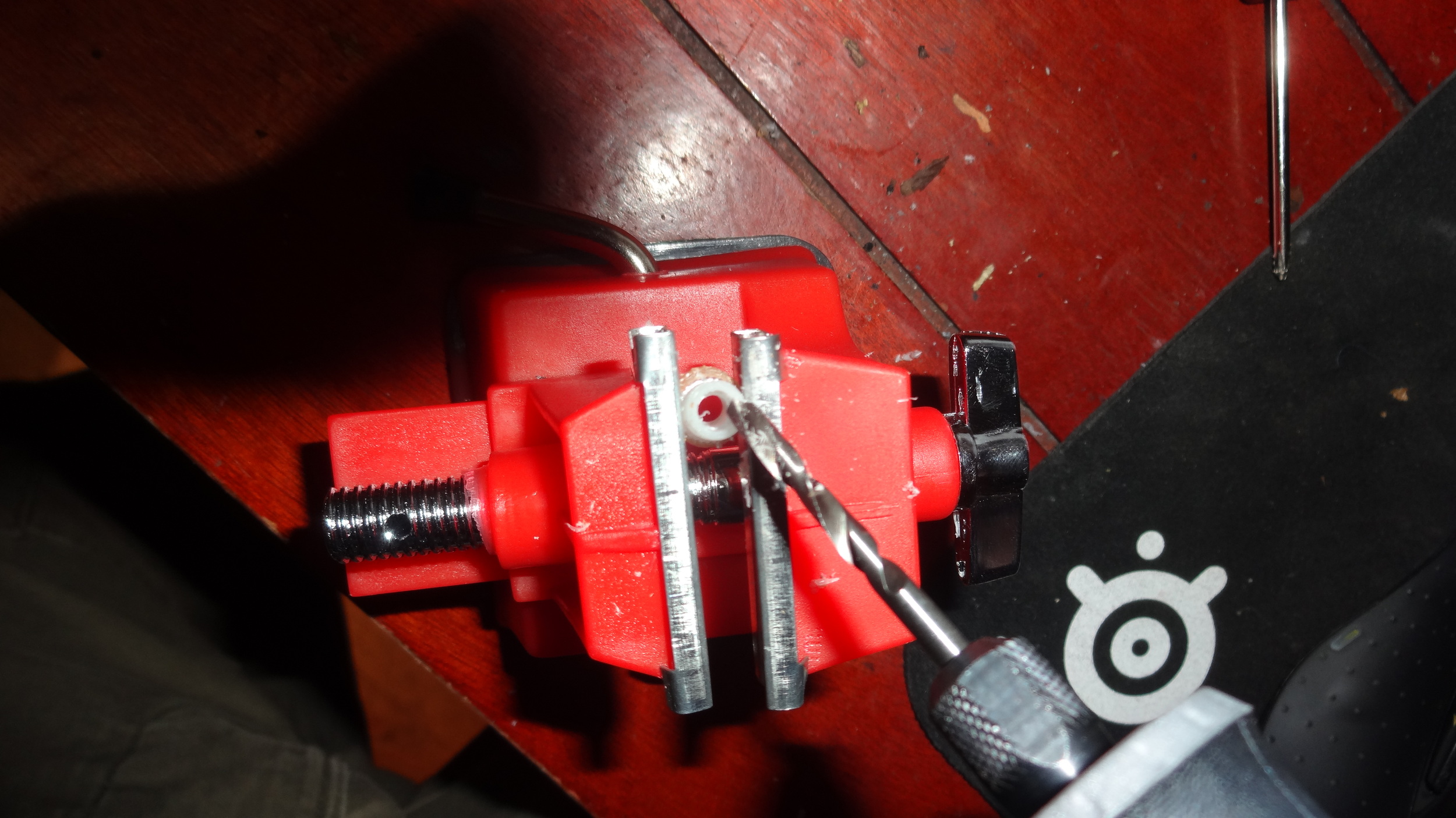

The software is currently still in an early beta mode, as is the hardware configuration. In the near future the existing servo will change to a step motor which moves the camera, this will provide a 360 degree view port and make the device all around more usable. I also did some investigation on the length of CSI cables (or limitations of length before degrading signals) - it seems people have gotten upwards 1 meter to work, I simply need enough to clear the 360 degree turn without stretching or bending the cable, and a meter is plenty. Not only that, I located a sturdy CSI extension cable on a random Polish web site for dirt cheap, so they are on the way.

Demonstration of CLI and Web client.

All code for PiTurretCam is tracked on github under the darkphotonworks organization under piturretcam repository.